Sterile Product Manufacturing

Manufacturing sterile products is essential in the pharmaceutical and bio-technology industries to guarantee the safety and efficacy of medicines and medical devices. Sterility is an essential requirement to prevent any contamination that could harm patient health. It is therefore important to be familiar with the various stages of this process.

Customized Technical Solution

Static and Dynamic protection

Quick installation and Implementation

Easy Surface Cleaning

Would you like an estimate for your project?

Do not hesitate to contact us for a personalized quote.

Key Steps in the manufacture of sterile products

The first stage in the manufacture of sterile products is the preparation of the raw materials. Each component must be rigorously tested to ensure that it is pure and free from contamination. Raw materials are often sterilised before being used, for example by filtration or irradiation. Next comes formulation, where the active ingredients are mixed with excipients to create the final product. This stage takes place in controlled environments to avoid contamination.

The next stage is aseptic filling. Here, the product is transferred into its final containers, such as vials, ampoules or syringes. This process takes place in class A or B clean rooms to prevent contaminants from entering. Once filling is complete, the containers are hermetically sealed to prevent further contamination. Each unit is then inspected for visible defects or contamination.

After this, final sterilisation is applied to products that cannot be sterilised before filling. The methods commonly used for this are moist heat sterilisation (autoclave), dry heat sterilisation or irradiation. Finally, quality control is carried out at every stage of the manufacturing process. Samples are regularly taken and tested for compliance with specifications. These tests include microbiological controls, sterility tests and physico-chemical checks.

Sterilisation technologies used in manufacturing

To ensure the complete elimination of microorganisms, the first method used is moist heat sterilisation, or autoclave. This technology uses pressurised steam to kill microorganisms and is effective for equipment, packaging materials and certain pharmaceutical products.

Another form of sterilisation is dry heat sterilisation, which uses hot air to destroy contaminants. This method is particularly useful for moisture-sensitive materials such as powders and oils. There is also irradiation, such as gamma rays or electron beams. This technology is used to sterilise products that cannot withstand heat. It is commonly used for medical devices, packaging and certain heat-sensitive pharmaceutical products.

Finally, there is filtration sterilisation, which is suitable for liquids and gases. Membrane filters, generally made of polysulphone or polyethersulphone, are used to trap microorganisms to ensure the sterility of the filtered product.

EREA Pharma: a leader in the manufacture of sterile products

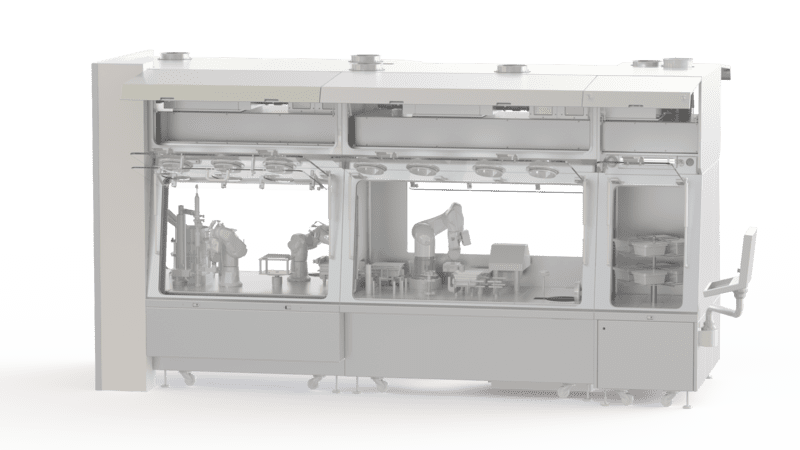

If you’re looking for a world leader in the manufacture of sterile products, EREA Pharma could well meet your needs. With many years of expertise and a state-of-the-art infrastructure, we can offer you complete solutions to meet the requirements of the pharmaceutical industry. Our manufacturing facilities are equipped with the most advanced technologies for sterile production, and our Class A and B cleanrooms are maintained to high standards of cleanliness and environmental control.

Quality is at the heart of our company’s mission. In fact, every stage of the manufacturing process is subject to rigorous quality controls. Regular internal and external audits also ensure that quality standards are always met.

Our commitment to continuous improvement enables us to maintain our leading position in the industry. Finally, we constantly invest in research and development to stay at the forefront of technological innovation. The adoption of new technologies, including advanced automation and computer vision systems, improves the efficiency and precision of our sterile manufacturing processes.

The manufacture of sterile products is a complex and rigorously controlled process, essential to the safety and efficacy of pharmaceutical products. With its technical expertise, advanced infrastructure, commitment to quality and continuous innovation, EREA Pharma is an undisputed leader in this field.

Would you like more information about our services? Please do not hesitate to contact us.

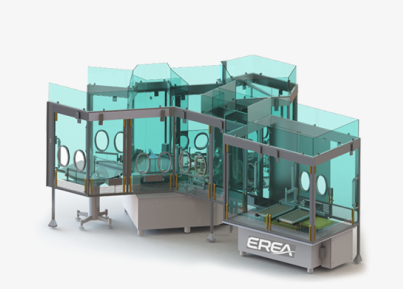

Our Isotechnical Products

Feasible adaptations, reliable sterile processes and tests, safe and fast handling: Erea has 30 years of experience at your service.

Do you have a question? Do you have a specific need? Don't hesitate to contact our technicians

Don't hesitate to contact us for personalised information about our isotechnical products.