Pharmaceutical Freeze Drying

Also known as cryodesiccation, freeze-drying is a preservation and stabilisation method widely used in the pharmaceutical industry. This process removes water from products, particularly medicines and vaccines, while preserving their stability and efficacy.

It is particularly useful for substances that are heat-sensitive or unstable in solution. Find out all you need to know about pharmaceutical freeze-drying on this page.

Customized Technical Solution

Static and Dynamic protection

Quick installation and Implementation

Easy Surface Cleaning

Would you like an estimate for your project?

Do not hesitate to contact us for a personalized quote.

Pharmaceutical freeze-drying process: stages and techniques

The first stage in pharmaceutical freeze-drying involves the freezing of the product. This takes place at extremely low temperatures, often below -40°C. This process transforms the water contained in the product into ice, which stabilises the active substances and prevents undesirable chemical reactions. Once the product is frozen, the next stage is primary sublimation.

In this phase, the pressure is reduced and heat is applied to allow the ice to transform directly into vapour without passing through the liquid state. This sublimation removes around 95% of the water contained in the product. Secondary drying is the final phase of freeze-drying and is designed to remove the residual water remaining after primary sublimation. This final stage uses slightly higher temperatures to eliminate the strongly bound water molecules. The product is thus stabilised, dry and ready for packaging and distribution.

Advantages of freeze-drying in the pharmaceutical industry

One of the main advantages of freeze-drying in the pharmaceutical industry is the stabilisation of pharmaceutical products. Thanks to this process, substances that are sensitive to heat and humidity, such as proteins, peptides and certain vaccines, can be preserved at room temperature without losing their biological activity.

Freeze-drying also considerably extends the shelf life of pharmaceutical products. By eliminating water, a medium conducive to microbial growth and undesirable chemical reactions, lyophilised products remain stable and effective for extended periods, even under variable storage conditions. Furthermore, freeze-dried products are often lighter and less bulky than their equivalents in solution, making them easier to transport and reducing logistics costs.

What’s more, reconstitution of these products is generally straightforward, meaning they can be administered quickly and effectively to patients. For some medicines, freeze-drying improves the solubility of the final product, making it easier for the body to administer and absorb. This is particularly beneficial for poorly soluble substances that require reconstitution before use.

EREA Pharma: experts in pharmaceutical freeze-drying

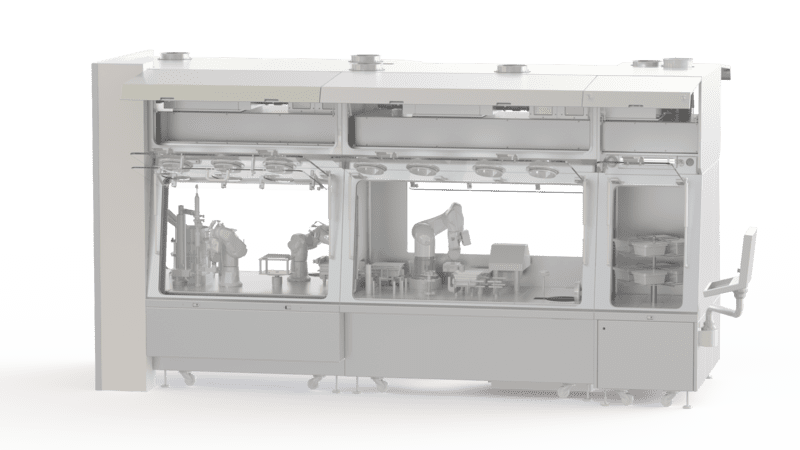

Freeze-drying is an essential process in the pharmaceutical industry, so it must be entrusted to an expert. EREA Pharma meets this criterion very well. We have technical expertise in all aspects of cryodrying. Our team of scientists and engineers develops optimised freeze-drying processes, guaranteeing product stability and efficacy.

In addition, our facilities are equipped with the most advanced freeze-drying technologies. In fact, our infrastructure includes large-capacity freeze-dryers and sophisticated environmental control systems. They can ensure ideal conditions for each stage of the process in question. Finally, we are committed to innovation in order to meet the industry’s emerging challenges and offer ever more efficient and reliable freeze-drying solutions.

Pharmaceutical freeze-drying is therefore an essential process for stabilising and preserving many pharmaceutical products. If you’re looking for a leading expert in this field, EREA Pharma is here to meet your needs.

To find out more about our services, please contact us.

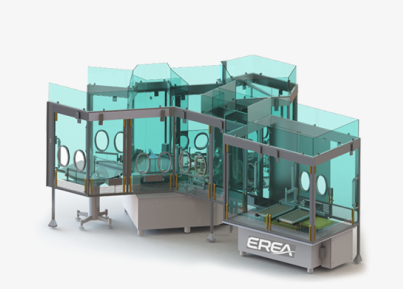

Our Isotechnical Products

Feasible adaptations, reliable sterile processes and tests, safe and fast handling: Erea has 30 years of experience at your service.

Do you have a question? Do you have a specific need? Don't hesitate to contact our technicians

Don't hesitate to contact us for personalised information about our isotechnical products.