Freeze-drying: Advantages and Disadvantages

Also known as desiccation, freeze-drying is a product preservation technique that has gained ground in many industries, including pharmaceutical, food and bio-technology.

In fact, this method mainly consists of removing the water from a product while keeping it in a solid state, allowing prolonged preservation without altering its chemical structure. It offers a number of interesting advantages. However, it also has its share of negative points. Let’s take a look at the advantages and disadvantages of freeze-drying.

Customized Technical Solution

Static and Dynamic protection

Quick installation and Implementation

Easy Surface Cleaning

Would you like an estimate for your project?

Do not hesitate to contact us for a personalized quote.

What is Freeze-drying?

Freeze-drying is a multi-stage process that begins with the freezing of the product concerned. Once frozen, it is placed in a vacuum freeze-drying chamber. The reduced pressure then allows the water to pass directly from the solid state (ice) to the gaseous state (vapour). It should be noted that this process effectively improves the water while preserving the product’s qualities.

This technique is widely used to preserve heat-sensitive substances such as vaccines, medicines, dehydrated foods and even micro-organisms. It allows long-term preservation without compromising the quality of the product.

What are the Advantages and Disadvantages of Freeze-Drying?

As we explore the advantages and disadvantages of freeze-drying, let’s look first at its strengths. First and foremost, this process preserves the characteristics of the freeze-dried product, including its structure, taste and nutritional quality, making it an ideal method for food and pharmaceutical products. Treated products also have a longer shelf life than other preservation methods. This is of course essential for pharmaceutical products, which often need to be stored for long periods. By eliminating the water, freeze-drying considerably reduces the weight and volume of products, making them easier to transport and store.

Despite these many advantages, this process is unfortunately complex and requires specialised equipment, resulting in high costs both in terms of equipment and energy used. In addition, freeze-drying can be a slow process, particularly for complex products. Productivity and production times can therefore be affected. Finally, freeze-drying operations require a certain amount of technical expertise and constant monitoring. This can make the process even more complex compared to other preservation methods.

EREA Products: Excellence in Freeze-Drying

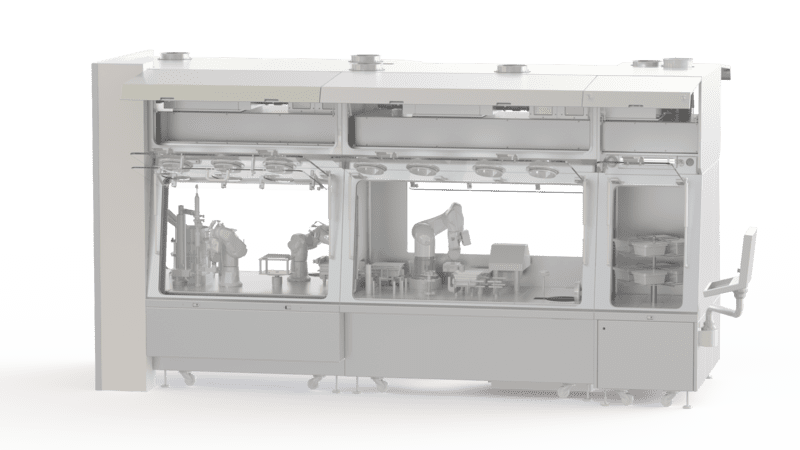

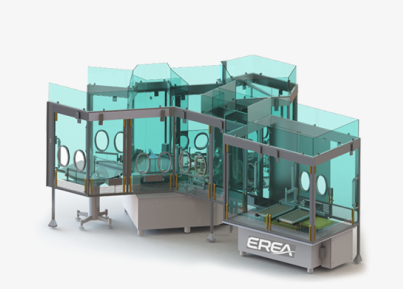

EREA has positioned itself as a leader in the design and manufacture of freeze-drying equipment. Among other things, our GMP pharmaceutical freeze-dryers comply fully with pharmaceutical industry standards. In fact, our equipment is designed to guarantee homogeneous and efficient freeze-drying while complying with safety and quality requirements. In addition to our freeze-dryers, we offer isolators with freeze-drying equipment.

This means we can offer a complete solution for pharmaceutical operations. These isolators ensure a sterile environment during the freeze-drying process to minimise the risk of contamination. However, our commitment to innovation is reflected in our products, with advanced features such as automatic process control, real-time monitoring and compliance with the latest regulations.

In short, we’re dealing with an essential preservation technique in many industries, and freeze-drying: there’s no shortage of advantages and disadvantages. In all cases, EREA’s excellent freeze-drying products help to alleviate some of the challenges facing this process. In particular, our company offers state-of-the-art solutions to meet the needs of the pharmaceutical industry.

Our Isotechnical Products

Feasible adaptations, reliable sterile processes and tests, safe and fast handling: Erea has 30 years of experience at your service.

Do you have a question? Do you have a specific need? Don't hesitate to contact our technicians

Don't hesitate to contact us for personalised information about our isotechnical products.