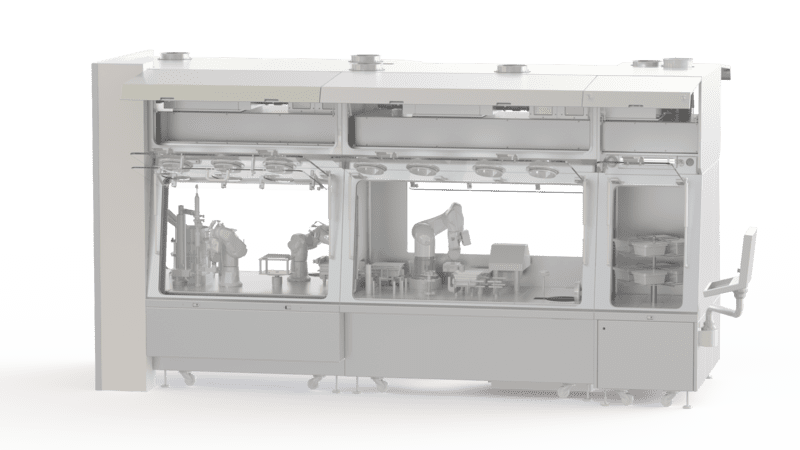

Fully Automated Gloveless Aseptic Robotic Filling Line

The fully automated gloveless aseptic robotic filling line is a revolutionary advancement in biopharmaceutical manufacturing. Designed to ensure sterility and precision, this technology minimizes contamination risks and enhances the efficiency of syringe and other injectable product production.

Customized Technical Solution

Static and Dynamic protection

Quick installation and Implementation

Easy Surface Cleaning

Would you like an estimate for your project?

Do not hesitate to contact us for a personalized quote.

Advantages of Full Automation

Fully automated systems eliminate the need for gloves and human intervention, thus reducing contamination risks. Moreover, they offer increased precision and reproducibility, ensuring that each product meets the highest quality standards.

Features of Robotic Technology

Precise and Flexible Handling

Robotic technology allows for precise and flexible handling of syringes, vials, and other containers. Robots can be programmed to handle different formats and volumes, providing great adaptability to varied production needs.

Controlled Aseptic Environment

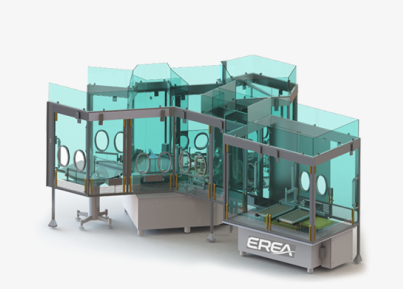

Robotic filling lines operate in controlled aseptic environments, using isolator-barrier systems to maintain sterility. This ensures that products are not exposed to contaminants during the filling process.

Real-Time Monitoring and Control

Automated systems integrate advanced real-time monitoring and control technologies. This allows for immediate detection of anomalies and quick adjustments to maintain the quality and efficiency of the filling process.

Impact on Biopharmaceutical Production

Increased Productivity

Robotic filling lines increase productivity by reducing cycle times and allowing continuous production. Downtime is minimized and production capacity is maximized.

Cost Reduction

Full automation reduces labor costs and human errors, which decreases the need for rework and product disposal. This translates to increased operational efficiency and significant cost savings.

Regulatory Compliance

Robotic technology helps ensure compliance with the stringent regulations of the biopharmaceutical industry. Automated systems are designed to meet GMP (Good Manufacturing Practices) standards, ensuring product quality and safety.

The fully automated gloveless aseptic robotic filling line represents a major advancement in biopharmaceutical manufacturing. By combining precision, flexibility, and strict sterility control, this technology is transforming the production of injectable medications, offering significant benefits in terms of productivity, cost, and quality.

Our Isotechnical Products

Feasible adaptations, reliable sterile processes and tests, safe and fast handling: Erea has 30 years of experience at your service.

Do you have a question? Do you have a specific need? Don't hesitate to contact our technicians

Don't hesitate to contact us for personalised information about our isotechnical products.