Manufacturing Science and Technology (MSAT) in Biopharmaceutical Production

What is Manufacturing Science and Technology (MSAT)? Manufacturing Science and Technology (MSAT) is a specialized field focused on improving and optimizing manufacturing processes in the biopharmaceutical industry.

By closely collaborating with R&D scientists, MSAT focuses on analyzing and enhancing workflows for cell culture media preparation to ensure the safety and quality of biological products.

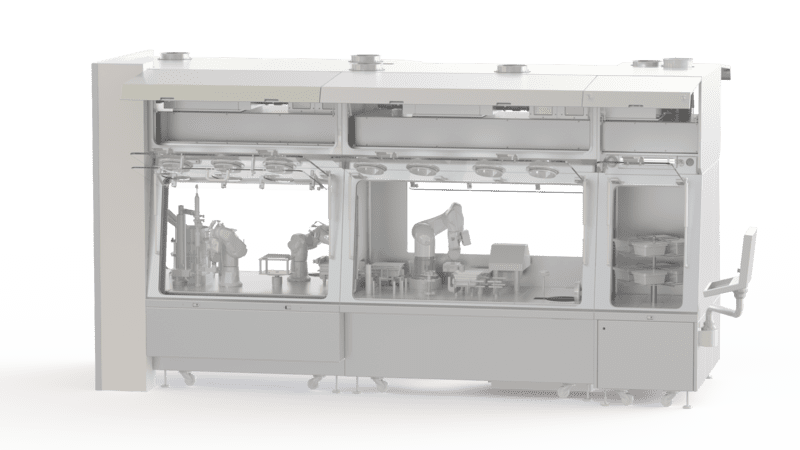

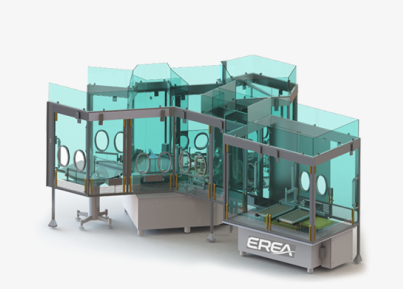

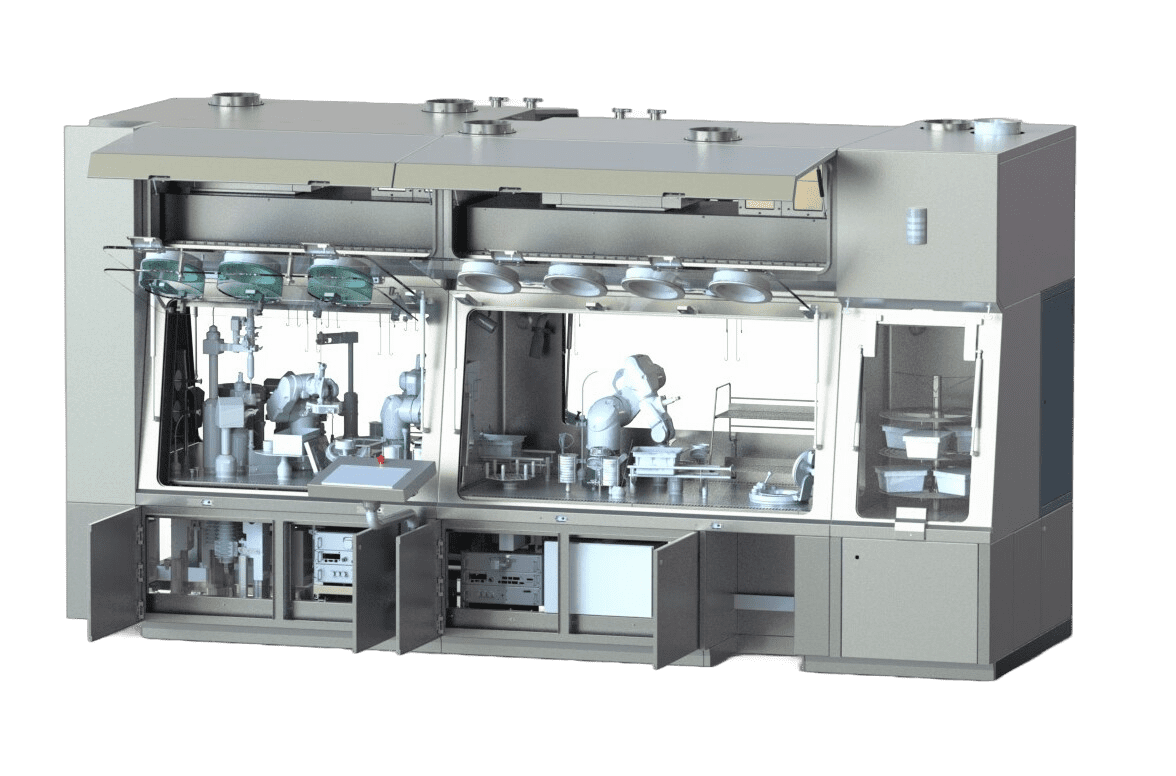

Customized Technical Solution

Static and Dynamic protection

Quick installation and Implementation

Easy Surface Cleaning

Would you like an estimate for your project?

Do not hesitate to contact us for a personalized quote.

Importance of MSAT in Biopharmaceutical Manufacturing

MSAT plays a crucial role in reducing risks and costs associated with advanced development stages. It streamlines media and buffer preparation processes, minimizes human interventions, and optimizes overall manufacturing efficiency of drug substances.

Key MSAT Services

Process Improvement

Analyzing preparation and hydration strategies helps identify and resolve issues related to handling, mixing, and media consistency, thus enhancing the robustness of manufacturing processes.

Integration of Design Means

The design and engineering of cell culture media are integrated to create user-friendly formulas, reducing labor hours and supporting scalable production from lab scale to cGMP manufacturing.

Simplification of Handling Methods

Handling methods are optimized to reduce adjustment steps and improve media preparation, minimizing human intervention risks and ensuring continuous supply through lean manufacturing.

Benefits of Implementing MSAT

Improved Product Quality

MSAT enables continuous and precise process monitoring, ensuring that finished products meet the highest quality standards and ensuring patient safety.

Reduced Production Costs

By detecting process deviations early, MSAT reduces waste and rework, lowering overall production costs and optimizing resource use.

Increased Flexibility and Innovation

Integrating MSAT promotes innovation by allowing rapid and flexible process adjustments. It also facilitates adaptation to new technologies and changing regulatory requirements.

Manufacturing Science and Technology (MSAT) is essential for optimizing biopharmaceutical processes. By providing advanced solutions for process control and improvement, MSAT ensures the production of high-quality drugs efficiently and economically. Its continued adoption will transform the biopharmaceutical industry, bringing significant benefits to manufacturers and patients.

Our Isotechnical Products

Feasible adaptations, reliable sterile processes and tests, safe and fast handling: Erea has 30 years of experience at your service.

Do you have a question? Do you have a specific need? Don't hesitate to contact our technicians

Don't hesitate to contact us for personalised information about our isotechnical products.