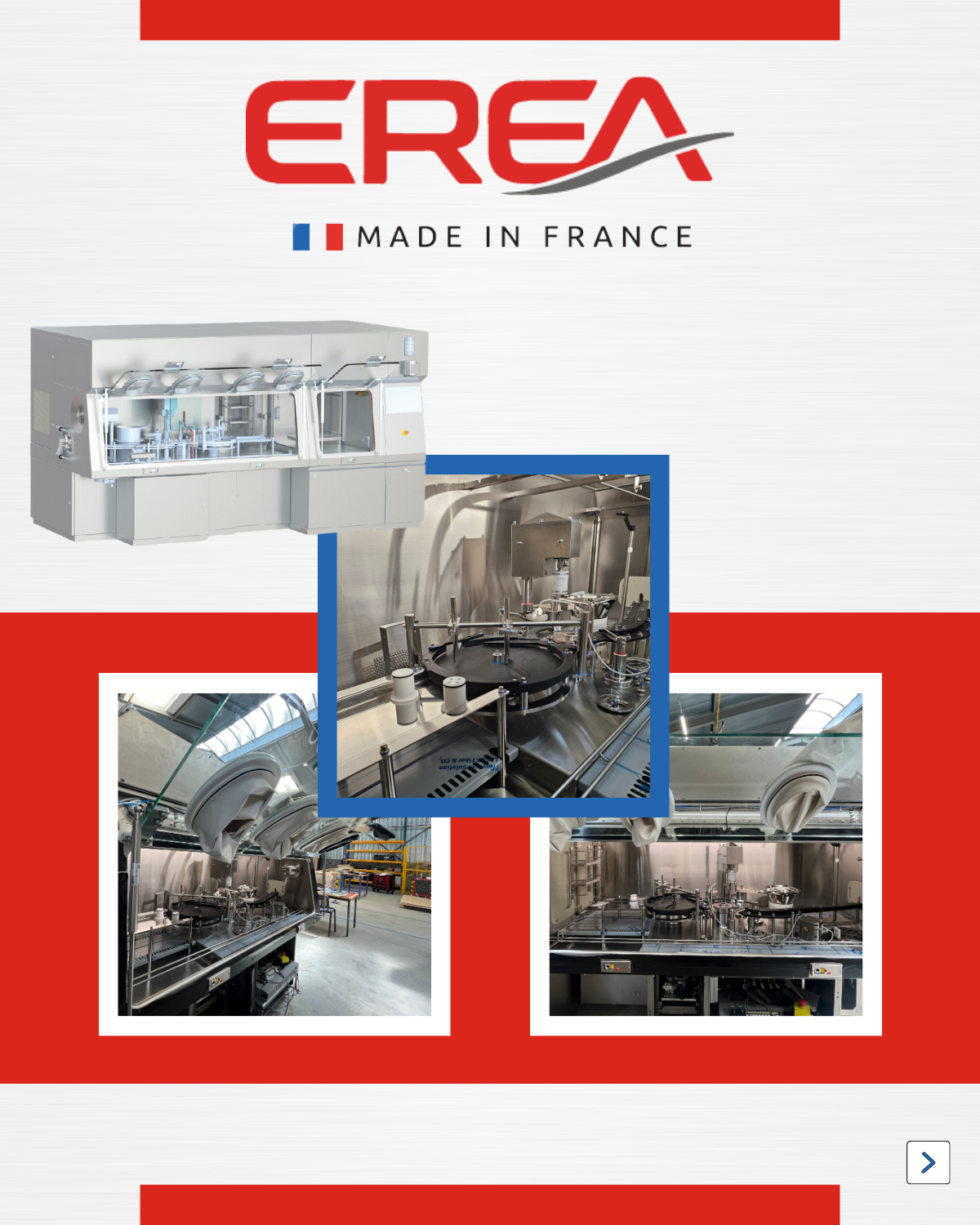

The final touches on our isolators for sterile application are in the process of being completed. This aseptic isolator, which incorporates a filling machine, is made of a 4 gloves main chamber of 2m long, a SAS transfer inlet, and a “Mouse Hole” trapdoor for parts removal.

One particular thing about that isolator is that the last chamber used for the installation is so small that the equipment’s height is of 2m only. The technical piece with the filtration elements are at the back of that chamber. This is another great achievement for a 100% custom made equipment by EREA PHARMA!

That made in france EREA equipment protects the product, the environment and the operator during the bottle filling and capping.

We hope that the customer will be satisfied by that equipment, and we to thank them for trusting us during this project.