Robotics in Aseptic Processing

Aseptic processing is a crucial method in biopharmaceutical manufacturing, aimed at preventing contamination and ensuring the sterility of drug products.

This process is essential for producing safe and effective medications, particularly injectable and parenteral drugs.

Customized Technical Solution

Static and Dynamic protection

Quick installation and Implementation

Easy Surface Cleaning

Would you like an estimate for your project?

Do not hesitate to contact us for a personalized quote.

The Role of Robotics in Aseptic Processing

Robotics play a significant role in enhancing aseptic processing by minimizing human intervention, which is a primary source of contamination. Robots are capable of performing highly repetitive tasks with precision and consistency, making them ideal for aseptic environments.

Advantages of Using Robotics

Enhanced Safety and Sterility

Robots can operate in environments where humans cannot, significantly reducing the risk of contamination. They generate low particulate levels and can be sanitized with sporicidal agents and vapor phase hydrogen peroxide (VPHP), ensuring a sterile production process.

Increased Productivity and Efficiency

Robotic systems enhance productivity by performing tasks continuously without fatigue. They also improve efficiency by reducing the time required for production cycles and minimizing the need for human intervention.

Flexibility and Adaptability

Robots offer flexibility in aseptic processing as they can be reprogrammed for different tasks and container formats with minimal investment. This adaptability is crucial for responding to changes in production requirements and regulatory standards.

Implementing Robotics in Aseptic Processing

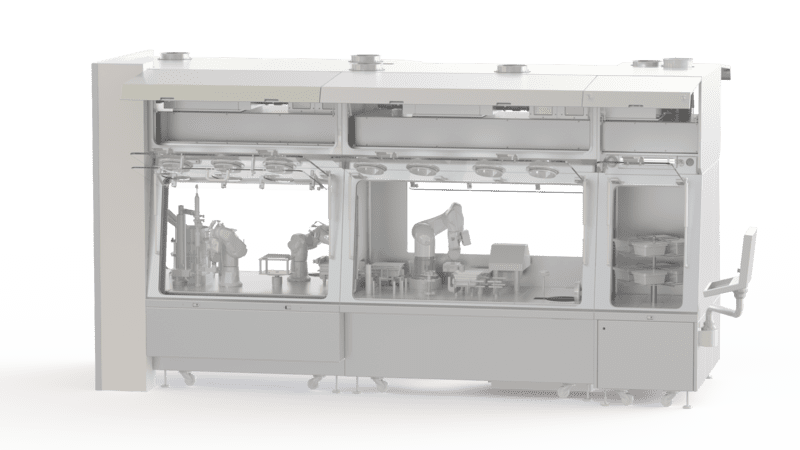

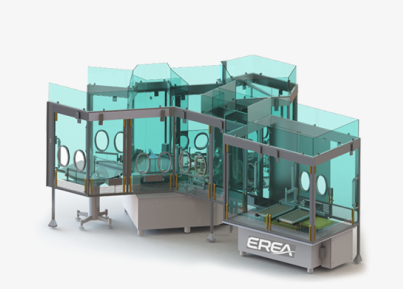

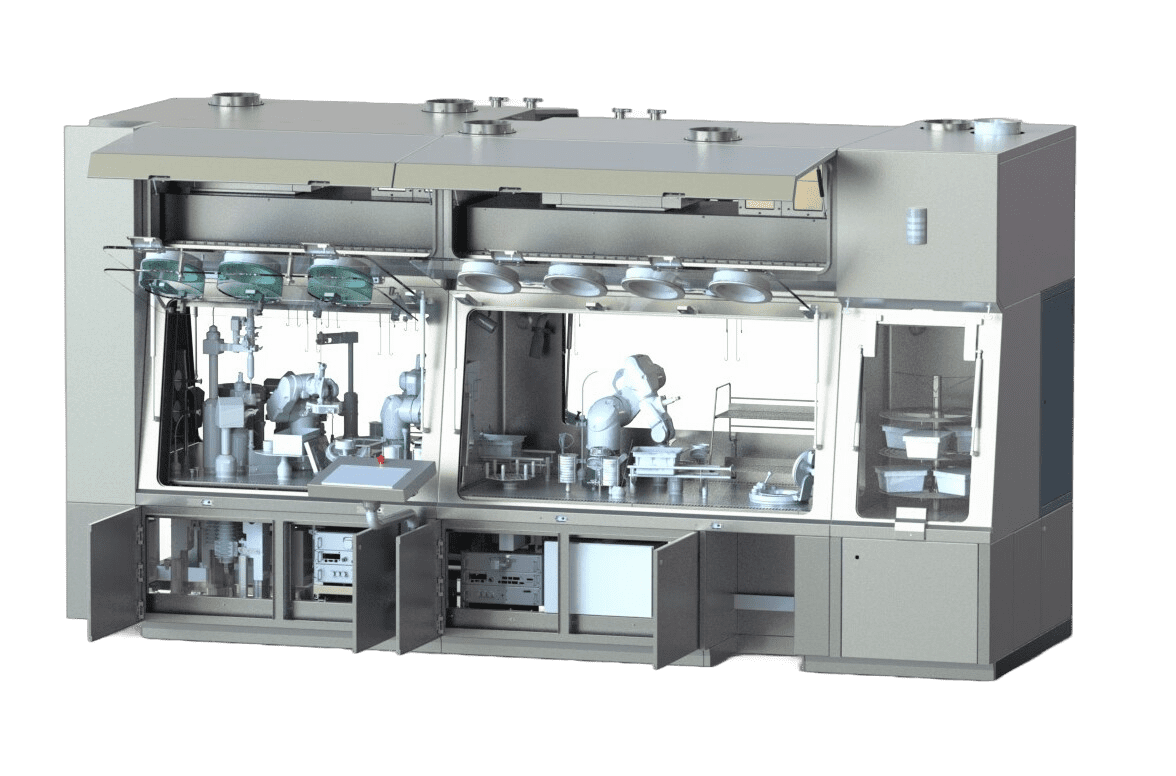

The integration of robotics into aseptic processing involves using advanced technologies such as machine vision, automated systems, and isolator-barrier systems. These technologies help maintain a controlled environment and ensure the highest levels of sterility and safety.

Case Study: EREA Pharma Robotics in Aseptic Processing

EREA Pharma has developed Production lines with robots specifically for aseptic production areas. These robots are designed to meet the stringent requirements of the pharmaceutical industry, offering reliability, precision, and sterility.

Robotics in aseptic processing represents a significant advancement in biopharmaceutical manufacturing. By reducing contamination risks, enhancing productivity, and providing flexibility, robots are transforming the way sterile drug products are produced. The ongoing development and integration of robotic technologies will continue to improve the efficiency and safety of aseptic processing in the pharmaceutical industry.

Our Isotechnical Products

Feasible adaptations, reliable sterile processes and tests, safe and fast handling: Erea has 30 years of experience at your service.

Do you have a question? Do you have a specific need? Don't hesitate to contact our technicians

Don't hesitate to contact us for personalised information about our isotechnical products.