Understanding Classification of Controlled Atmosphere Pharmaceutical Areas

Current regulations require perfectly controlled production environments for the manufacture of pharmaceutical products, certain medical devices and even cosmetics. These environments must be free from contamination in order to guarantee product quality and protect consumers.

The containment solutions deployed must be adapted to the process being carried out. In this article, EREA tells you more about the classification of controlled atmosphere pharmaceutical areas.

Customized Technical Solution

Static and Dynamic protection

Quick installation and Implementation

Easy Surface Cleaning

Would you like an estimate for your project?

Do not hesitate to contact us for a personalized quote.

Understanding the Classification of Controlled Atmosphere Pharmaceutical Areas

While cleanrooms must comply with ISO 14644 standards for contamination control, controlled atmosphere pharmaceutical areas require compliance with Good Manufacturing Practices (GMP). Their strict application guarantees the control of contaminants in sensitive areas. Industries and laboratories must deploy pharmaceutical areas that meet the requirements of these GMPs for their manufacturing processes for drugs or certain medical devices. These standards and regulations set the required level of particulate cleanliness for the containment devices used. The characteristics and performance of these devices must be adapted to the manufacturing process and the type of product handled.

Complying with the classification of controlled atmosphere pharmaceutical areas helps to protect consumers. Products are handled in a contaminant-free working environment. Throughout the manufacturing process, numerous tests are carried out, including at the end of the line, to check that processes and products comply with Good Manufacturing Practice (GMP) standards, particularly with regard to sterility. The classification also aims to protect operators and the environment when handling hazardous substances.

Classification of Controlled Atmosphere Areas

For the manufacture of sterile medicinal products, there are four GMP classes of controlled atmosphere areas: class A, B, C or D. It is not enough for areas to meet the criteria required by the corresponding class. They must also be subject to periodic microbiological monitoring.

Here are the specifics of each classification of controlled atmosphere pharmaceutical zones:

- Class A controlled atmosphere pharmaceutical areas: these are equipped with a laminar flow hood. They are used for high-risk operations. Class GMP at rest requires a maximum concentration per m3 of 3,520 particles of size 0.5 μm and 20 particles of size 5 μm.

- Class B controlled atmosphere pharmaceutical areas: these are used for aseptic preparation and filling operations. In these areas, the maximum concentration per m3 must not exceed 3,520 particles of size 0.5 μm and 29 particles of size 5 μm.

- Class C or D controlled atmosphere pharmaceutical areas: these are used for less critical work in the manufacturing process. For class C, the particle content must not exceed 352,000 per m3 for the 0.5 μm size and 2,900 per m3 for the 5 μm size. For class D, the maximum permitted concentration per m3 is 3,520,000 particles of size 0.5 μm and 29,000 particles of size 5 μm.

EREA Pharma, Experts in Containment Systems

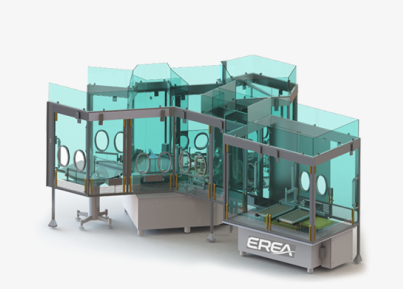

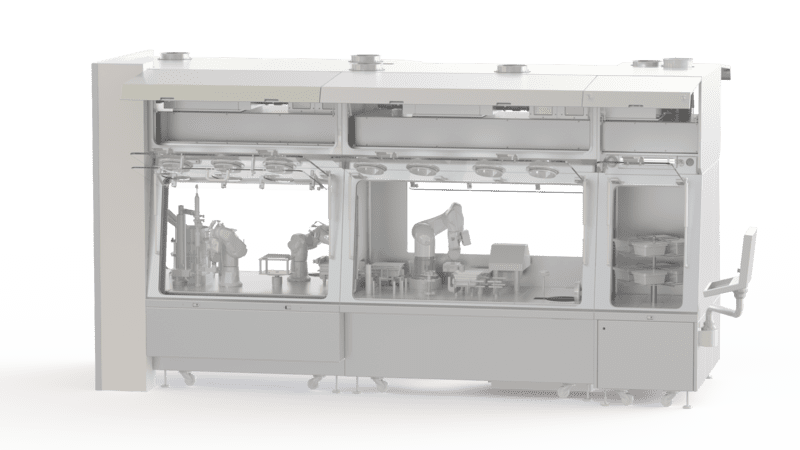

Do you need a containment system to guarantee the compliance of your pharmaceutical manufacturing processes? Call on EREA Pharma, the containment system specialist. We offer a range of containment solutions to meet the requirements of your sterile processes. Find out more about our isolators, restricted access barrier systems and other customised equipment. The classification of EREA controlled atmosphere pharmaceutical areas complies with Good Manufacturing Practice (GMP). Depending on the requirements and constraints of your pharmaceutical processes, we can offer you tailor-made solutions.

Find out more about our products and services by contacting our technical experts.

Our Isotechnical Products

Feasible adaptations, reliable sterile processes and tests, safe and fast handling: Erea has 30 years of experience at your service.

Do you have a question? Do you have a specific need? Don't hesitate to contact our technicians

Don't hesitate to contact us for personalised information about our isotechnical products.